A synchronous motor is type of alternating current (AC) motor that runs in synchronized speed with the frequency of applied alternating current (AC). The synchronous speed is the constant speed at which the magnetic field produced in a motor’s stator winding revolves, or it can be called as the constant speed at which electromotive force is produced by an alternating machine.

In a synchronous motor, the total number of shaft-rotation is precisely equal to the integral number of supplied AC cycle or frequency of applied current. Unlike any induction motor, a synchronous motor doesn’t rely upon induction current for functioning. Instead, this motor contains multiphase AC electromagnets on the stator that produces a rotating magnetic field, which rotates in sync with the frequency of supplied line current. It has a rotor with permanent electromagnets or magnets which gets synced with the stator’s rotating magnetic field and as a result turns in step with the stator’s magnetic field.

What is synchronous speed?

The synchronous speed of a motor is the constant speed at which the magnetic field produced by the stator of an alternating machine rotates.

The synchronous speed is determined by the following functions:

- The electrical frequency of the supplied alternating current, typically 60 Hz or 50 Hz.

- The number of poles in the motor.

The synchronous speed is calculated by multiplying the supply frequency by 60 and dividing by the number of pairs of poles. The synchronous speed of an AC motor is controlled by changing the stator frequency. The synchronous speed can be expressed by the following formula:

ns = f (2 / p) 60

Where,

ns = shaft rotation speed (rev/min, rpm)

f = frequency of electrical power supply (Hz, cycles/sec, 1/s)

p = number of poles

In reality, a synchronous motor can never reach its synchronous speed. Because if it did, the rotor would appear stationary relative to the stator’s rotating field, given that the rotor would rotate at the same speed. Without any relative motion between the stator and rotor magnetic field, no emf or voltage will be induced in the motor rotor. Therefore, the actual speed of a synchronous motor is limited to a speed below synchronous speed. Actual speed of a synchronous motor is roughly 3 to 5% less than synchronous speed. The difference between the actual speed and synchronous speed is called slip.

What is a synchronous motor used for?

Synchronous motors are rarely used for application below 40 kW. They are used for application where constant, precise and less (around 500 rpm) operating speed but great power is required.

The different types of applications for which synchronous motors are used can be classified as:

- Voltage regulation

- Power factor correction

- Constant speed constant load drives

Some of the general applications of synchronous motor are:

- Without attaching load to the shaft in an overexcited state, a synchronous motor is used for power factor correction

- Because of their characteristic higher efficiency, induction motors are used to drive loads which require constant speeds such as reciprocating mills, rolling meals, compressor and so on.

- They are used as voltage regulators at the end of transmission lines.

- With a variable frequency drive (VFD) system, synchronous motors are used in paper and textile mills to achieve a wide range of speed.

What are the principal parts of the synchronous motor?

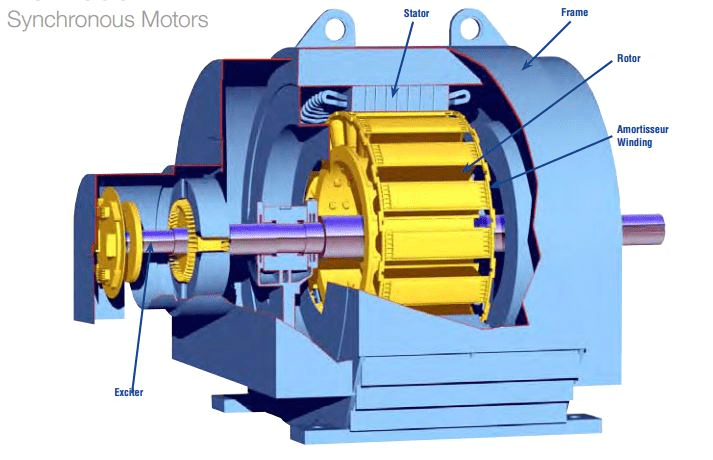

The structure of a synchronous motor is very similar to the construction of an alternator and asynchronous motor. Just like any other motor, the two main parts of the synchronous motor are a stator and a rotor.

The key components of the synchronous motor are:

- Stator: The stator is the stationary part of the motor. It comprises a stator frame or housing and a magnetic circuit comprising silicon steel lamination known as stator core and stator winding or a 3-phase coil supplied with 3-phase AC to produce a rotating field.

- Rotor: The rotor is the rotating part that rotates almost exactly at the same speed as the stator Field. The rotor carries permanent field magnets or coils, which are excited by a direct current (DC) source which create fixed polarity flux. The North Pole is created on one end of the rotor, and the South Pole is created on another end.

There are two types of rotors with wound coil are available according to the construction type- Salient pole rotors: The salient pole type rotor that has poles projecting out from the rotor surface. It comprises steel lamination to reduce eddy current loss.

- Non-salient pole rotors: Non-salient poles are the rotor types in which windings are placed in slots on the rotors.

- Exciter: This is a small direct-current generator that provides power to the electromagnets that form the poles on the rotor that follow the rotating magnetic field from the system. It comprises field winding, placed in the stator and armature winding, placed on the rotor of the synchronous motor.

A synchronous motor is doubly fed if it is installed with independently excited multiphase AC electromagnets on both the rotor and stator. - Frame: The frame of motor holds and protects all other parts of motors. It serves the user also from any casualty during high speed rotation of the shaft. Other than that, the ratings and other vital information about the motor is placed on the synchronous motor housing

How do you know if a motor is synchronous?

Unlike other AC motors, synchronous motor always runs at a speed equal to its synchronous speed. Synchronous motors also require an additional DC power source for energizing rotor winding. While, induction motors do not require any additional power source.

Just by visual inspection, you can know if a machine is a synchronous or an induction motor. A synchronous motor is a doubly excited motor, which means it needs both field and armature excitation. The field windings are excited with direct current source and the armature windings are excited with alternating current. So it is a four terminal machine.

Where as, an induction motor is a singly excited machine, which has only two terminals and always excited by an AC supply.

- Check if there is any field connection. If there is a field connection, then the motor is synchronous (assuming it can’t be a dc motor). Induction motor does not have any field connections but only stator supply.

- Also, if you know the number of poles in the machine and frequency of supply, you can calculate synchronous speed which is equal to (120xfrequency/number of pole) in r.p.m. If the motor is synchronous type, then the steady state speed will equal to synchronous speed but if it is induction motor steady state speed will be slightly less than synchronous speed.

The detail of the other difference between synchronous and asynchronous motor is given below:

- Synchronous motors require an extra Direct Current power source for energizing the rotor winding. Whereas induction motors do not require any such additional power source.

- Slip rings and brushes are essential for synchronous motors, but not in other AC motors except in wound type induction motor in which slip ring motors are used for adding external resistance to the rotor winding.

- Synchronous motors also require additional starting mechanism for initially rotating the rotor close to the synchronous speed. But no starting mechanism is required in induction motors.

- The power factor of a synchronous motor is adjustable to lagging, unity or leading by varying the excitation. But an induction motor always runs at a lagging power factor.

- Synchronous motors are more efficient than induction motors.

- Synchronous motors are costlier.

What are the features of synchronous motor?

Some principal features of the synchronous motor are:

- Synchronous motors are inherently not self starting.

- They require some external rotating mechanism to bring their speed close to synchronous speed to before they get synchronized.

- The speed of operation of is in synchronize with the supply frequency.

- When supply frequency is constant, they behave as constant speed motor irrespective of load condition.

- Synchronous motor has the unique characteristics of operating under any electrical power factor. This is the reason it is used in electrical power system for power factor improvement.

The advantages of Synchronous motors are:

- It can control the power factor. An over excited synchronous motor has leading power factor, when operated in parallel to induction motors improves system power factor.

- Speed remains constant regardless of the load. This helps in industrial application where constant speed is required irrespective of the load.

- Synchronous motors are mechanically more stable because they are built with wider air gaps than induction motors.

- Electromagnetic power of the synchronous motor is directly proportional with the voltage in synchronous motors.

- Synchronous motors usually operate with higher efficiencies, which is more than 90%, especially in low speed compared to induction motors.

The disadvantages of synchronous motor are:

- Synchronous motors require separate direct current excitation.

- These motors are not self-starting motors because they need some external rotating system for its starting and synchronizing.

- The cost per kW power output is higher than cost per kW output power of induction motors.

- Unless the incoming supply frequency is adjusted, there is no possible way to adjust the speed.

- Because these motors have zero starting torque, they cannot be started on-load condition.

- Collector rings and brushes are required which results in high maintenance cost.

Synchronous motors will not be effective for applications where frequent starting of machines are required.